Elemental Analysis

Optical Emission Spectroscopy (OES) reveals the specific elemental constituents of your material. By showing the exact percentage of each element present in your test sample, you can verify conformance to your required specification or confirm which alloy was actually used to make a component.

As well as highly sensitive vacuum-based photomultiplier tube (PMT) spark excitation optical emission spectrometers, MTT now employs high performance Charged Couple Device (CCD) desktop spectrometers with a wavelength coverage between 130 and 680nm.

To use OES, your sample must be a conductive metallic solid with a diameter of 5mm or greater.

Mechanical Testing

Our mechanical test house evaluates mechanical properties, including strength, hardness, ductility, impact resistance, fracture toughness, elongation, and stress.

By testing your sample to destruction, and recording the results, you can be confident your product will perform as intended in your desired application.

Sub-zero Charpy impact testing gives you confidence in your material by measuring the energy absorbed during fracture, which indicates the relative toughness. This enables you to draw conclusions about the ductility or brittleness of your material under impact conditions and the ductile to brittle transition temperature. We offer Charpy impact tests from ambient temperature to -130°C and at -196°C.

We are accredited to carry out tensile tests with forces up to 500kN and elevated temperatures up to 650°C. Testing produces a force-elongation curve whilst your test piece undergoes deformation. The strength properties of your material are calculated and compared with the upper and lower limits required by the material specification.

You may provide your own test pieces for analysis or our machine shop will prepare your sample free of charge prior to testing.

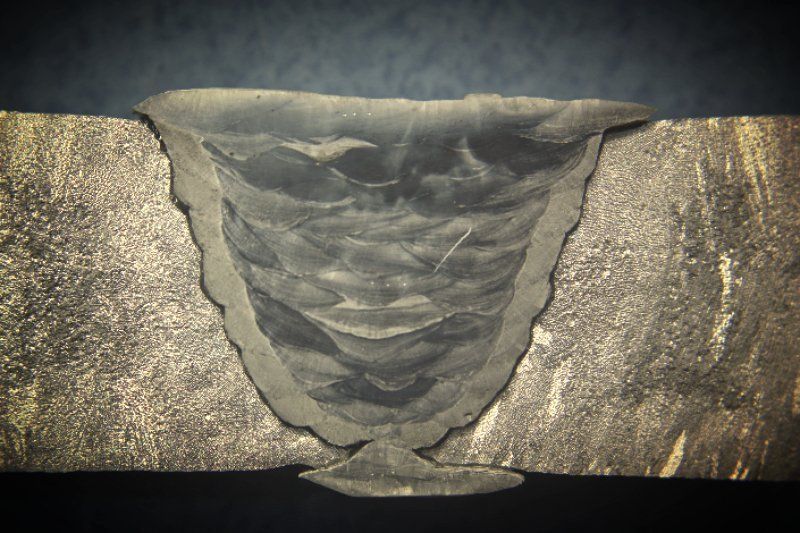

Metallographic Testing

Metallographic testing is the fine examination of the structure of your sample at the macro-and-microscopic level.

The careful preparation of your sample by our material testers is crucial. Once a representative sample has been chosen, there are five preparation processes, carried out by hand: sectioning, mounting, grinding, polishing, and etching, which reveals the grain structure, including any surface defects.

Testing aims to evaluate the extent of decarburisation, the grain size, intergranular corrosion, inclusion content, the volume fraction of various phases, and identify the microstructures present in your sample, which significantly govern your material's mechanical properties like strength, toughness, and ductility.

Corrosion Testing

Your products are destined to operate within a particular environment and with a projected service life.

We can simulate adverse environmental conditions using different catalysts to identify localised attack, expose pitting sites which may lead to crack initiation, and calculate the surface corrosion rate.

The National Association of Corrosion Engineers (NACE) estimated the annual global cost of corrosion

amounted to at least $2.5 trillion, or about 3.4% of the world’s GDP as of 2013. We help you to understand why and where corrosion occurs, so that you can deploy suitable protection methods such as coatings or sacrificial layers to reduce the long-term costs of corrosion.

Failure Investigations

Sometimes metal products fail to perform as expected. This can lead to loss of business, damage to property or the environment, and may lead to litigation. In the worst case scenario, death or injury may be caused, for example, in the case of an unexpected catastrophic rupture of a loaded component subjected to metal fatigue.

We work closely with you to analyse your failed component at the macro-and-microscopic level to determine the likely cause and indicate possible solutions.

We record all our observations and conclusions in a comprehensive failure investigation report

with annotated photomicrographs, so you will know what to do next.

Consultation

MTT can advise you on your choice of service with no upfront fees. Our metallurgists and material testers offer several years combined knowledge and experience to help you to assess your testing requirements and comment on your test results.

If you need more detailed advice and recommendations, for example technical assistance with a new project, or a solution to a particular metallurgical problem, we can assist you as part of a formal metallurgical consultation.

Consultations are arranged on or off site as required and priced on a case-by-case basis. Please contact us for details.

Other Services

We offer a range of other metallurgical services such as:

- Weld and welder approvals

- Jominy end-quench testing (hardenability)

- A full range of heat treatments prior to testing (annealing, case hardening, precipitation strengthening, tempering, carburising, normalising, quenching)

- Preparation processes only such as sawing and machining

These services may fall outside the scope of our laboratory accreditation. Please contact us for more information.