Accreditation

Accreditation

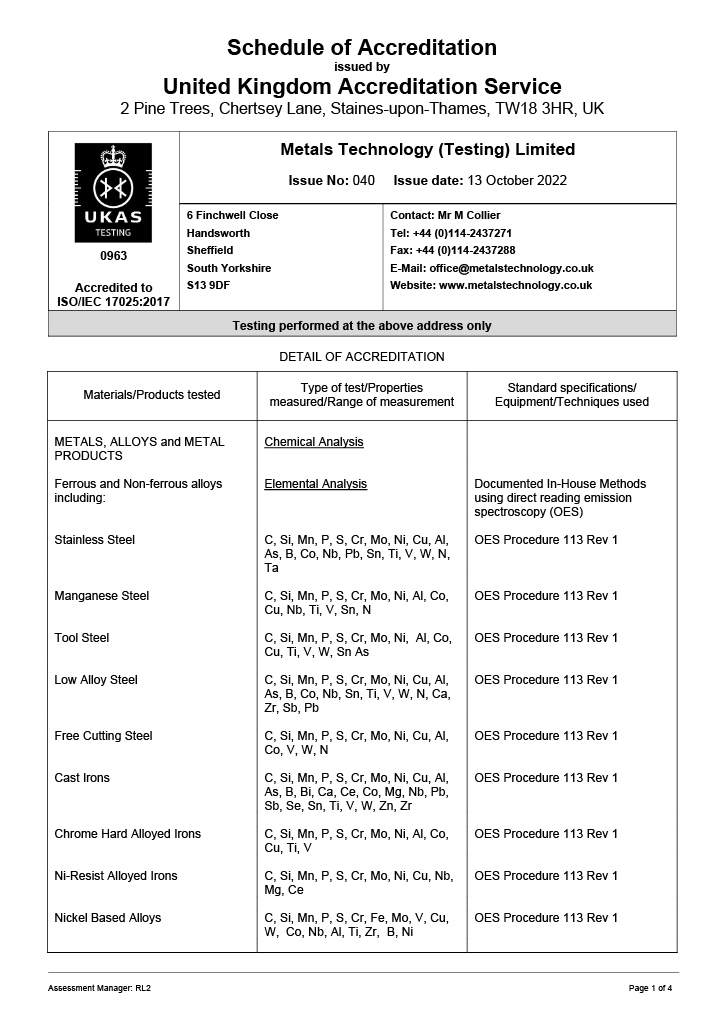

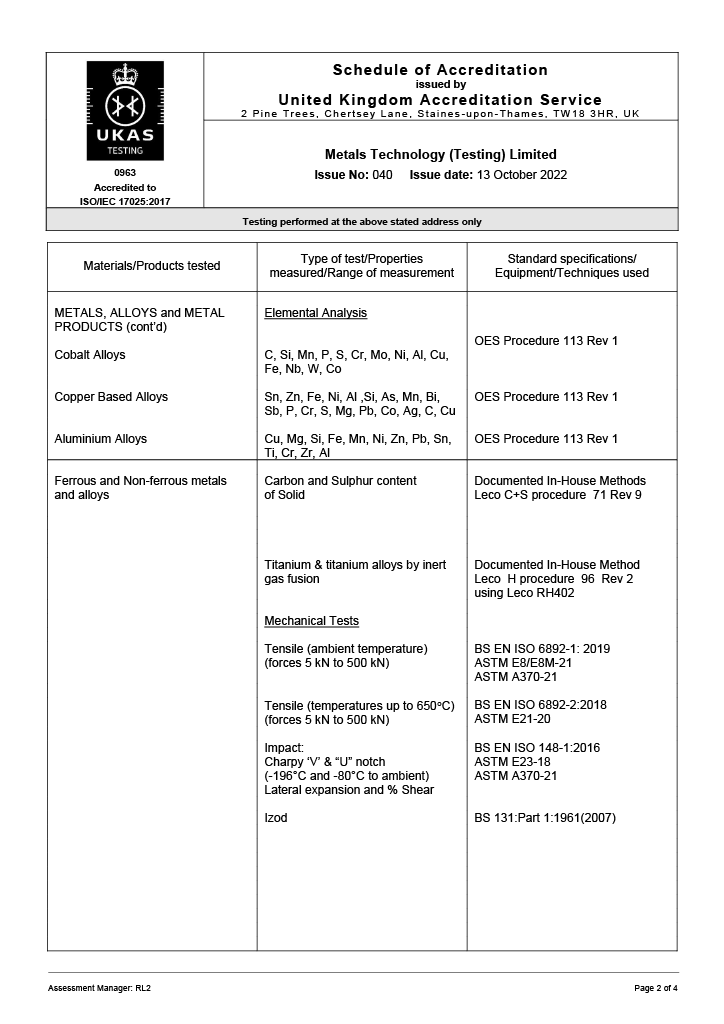

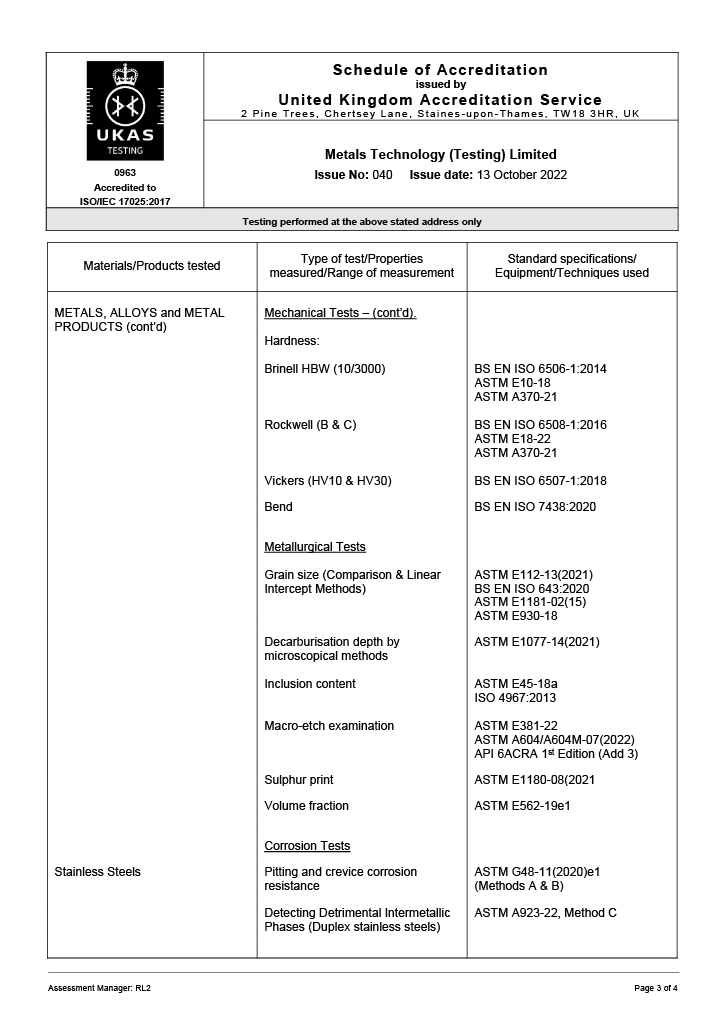

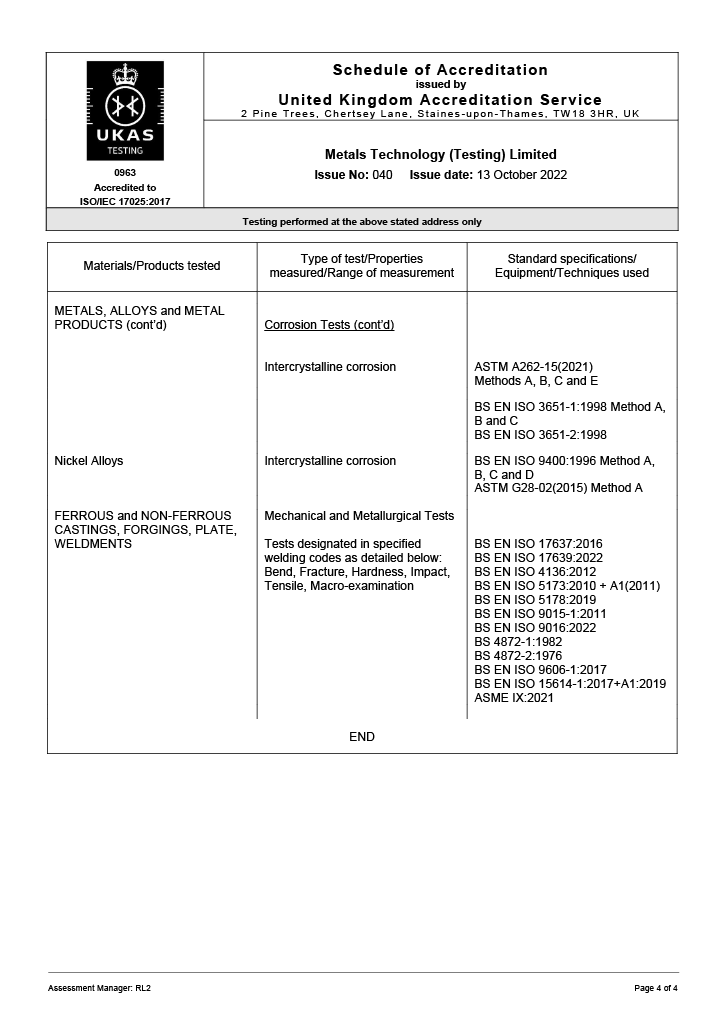

This laboratory is accredited in accordance with the recognised international standard ISO/IEC 17025. This accreditation demonstrates technical competence for a defined scope and the operation of a laboratory quality management system (refer joint ISO-ILAC-IAF communiqué dated April 2017).

As well as ISO/IEC 17025 accreditation, MTT is a Cameron

approved vendor (Cameron Approved Vendor No. 10154648) and ClydeUnion Pumps

Nuclear Approved Vendor in the supply of testing services for nuclear and safety-related applications (audited by ClydeUnion Pumps in accordance with ASME III, NCA 3800).

We are committed to continual improvement of the quality management system. This takes the shape of regular internal audits, anticipating technological changes and scientific developments, improving communications with our clients, and soliciting feedback.

MTT has fully equipped, well maintained and periodically calibrated instruments with a competent team of technologists to provide precise, accurate, and reliable determination of your test results.

Below you will find a list of our accredited tests.

Other metallurgical tests and services may be available on application.

For metal testing advice or a quote call us now:

0114 220 1900

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

UK

0114 243 7271

uksales@mttesting.com

N. AMERICA

+1 650-437-7377

usasales@mttesting.com

INTERNATIONAL

+44 114 220 1900

globalsales@mttesting.com

Registered in England & Wales: 02159849

Copyright © 1997–2024 Metals Technology Testing Ltd.