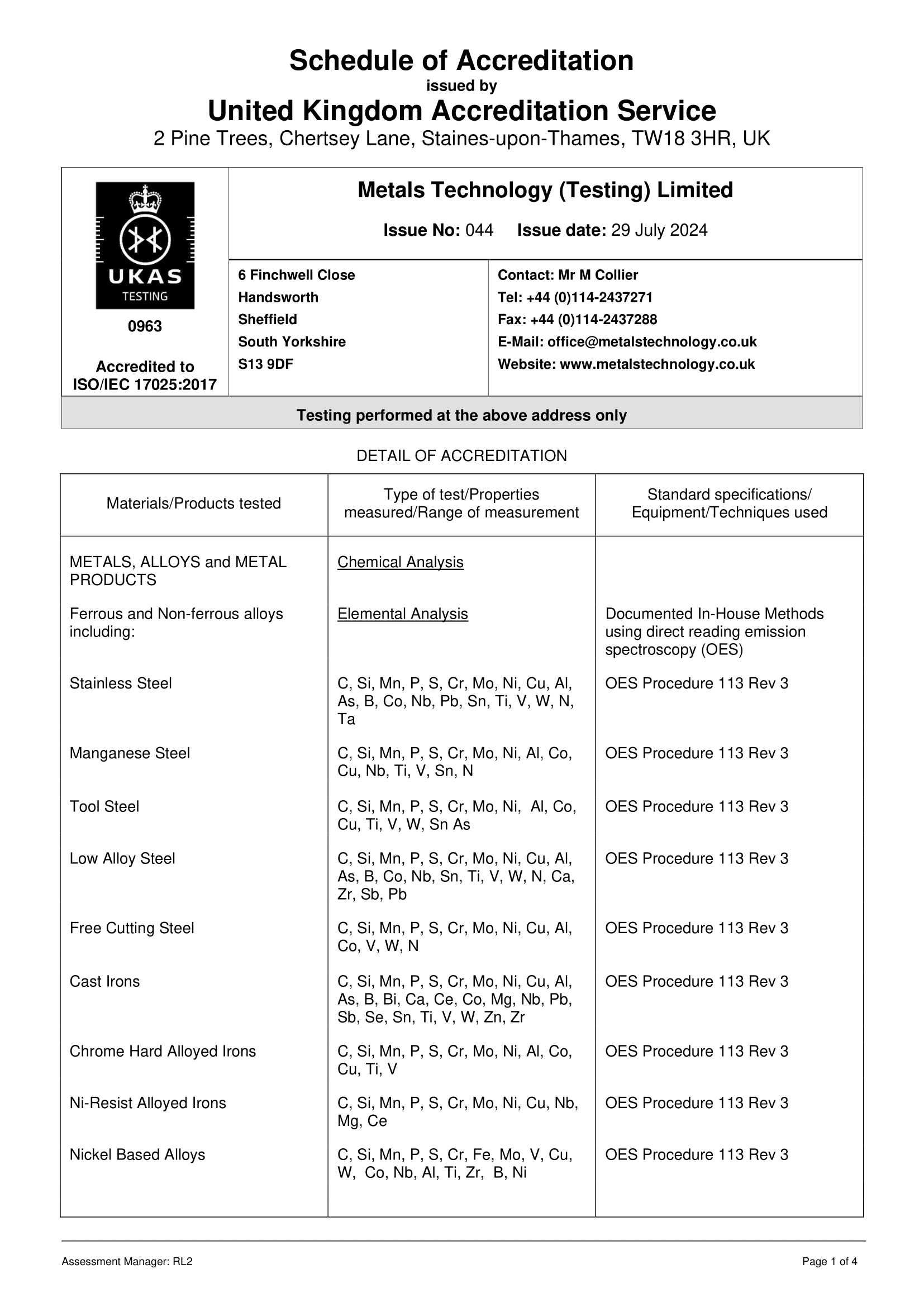

Accredited Tests

This laboratory is accredited by the United Kingdom Accreditation Service (UKAS) in accordance with the recognised international standard ISO/IEC 17025. This accreditation demonstrates technical competence for a defined scope and the operation of a laboratory quality management system.

As well as ISO/IEC 17025 accreditation, MTT is a Cameron approved vendor (Cameron Approved Vendor No. 10154648) and ClydeUnion Pumps Nuclear Approved Vendor in the supply of testing services for nuclear and safety-related applications (audited by ClydeUnion Pumps in accordance with ASME III, NCA 3800).

We are committed to continual improvement of the quality management system. This takes the shape of regular internal audits, anticipating technological changes and scientific developments, improving communications with our clients, and soliciting feedback.

MTT has fully equipped, well maintained and periodically calibrated instruments with a competent team of technologists to provide precise, accurate, and reliable determination of your test results.

List of Accredited Tests

Elemental Analysis

Elemental analysis aims to determine the composition of your sample, which significantly governs its properties. We are accredited to analyse the following metallic material types using standardised and documented in-house methods:

- Stainless Steel

- Manganese Steel

- Tool Steel

- Low Alloy Steel

- Free Cutting Steel

- Cast Irons

- Chrome Hard Alloyed Irons

- Ni-Resist Alloyed Irons

- Nickel Based Alloys

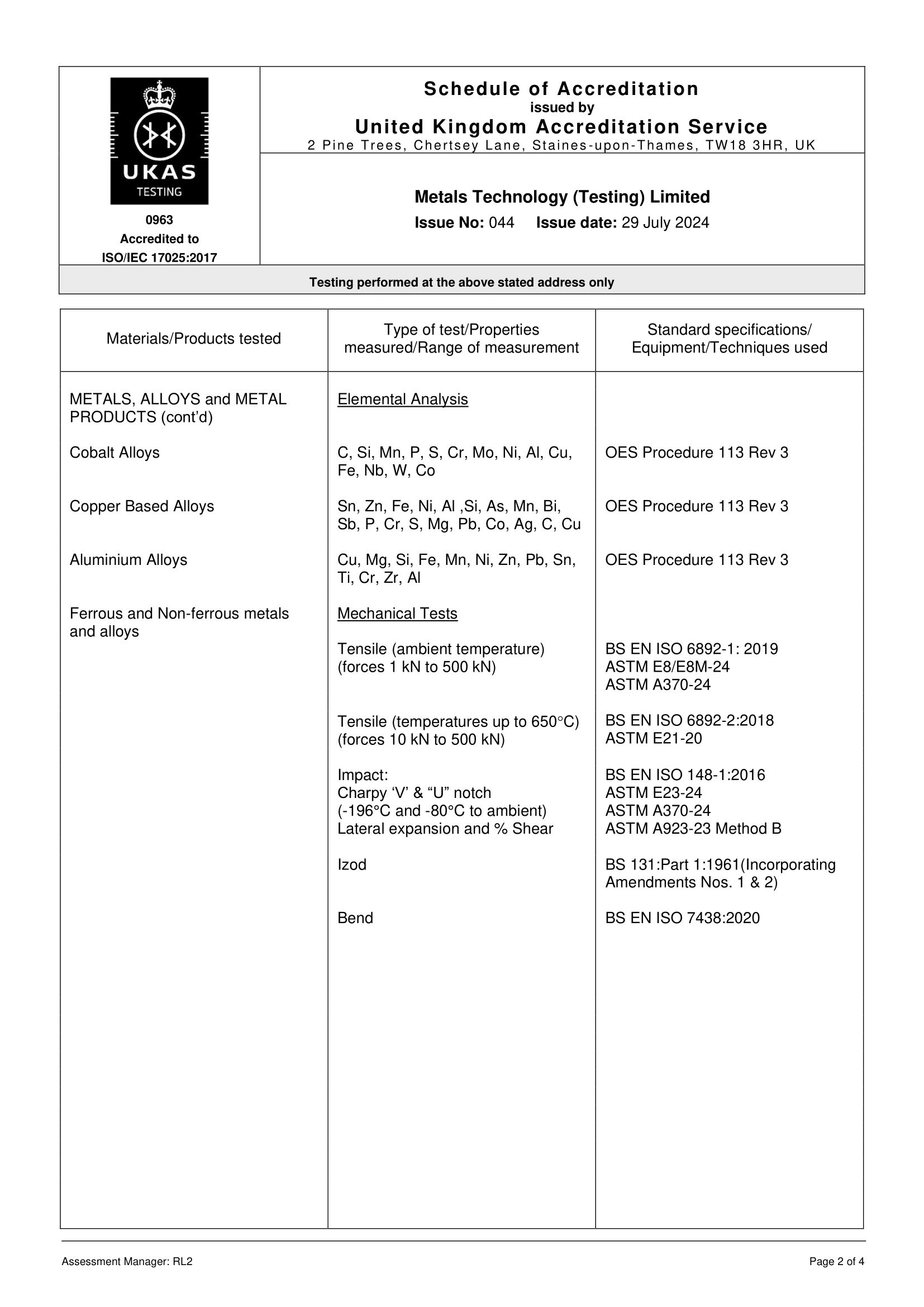

- Cobalt Alloys

- Copper Based Alloys

- Aluminium Alloys

Mechanical Tests

Mechanical tests involve evaluating your material's mechanical properties like strength, hardness, and ductility. By subjecting your material to various forces and observing its response, you can ensure your products meet standards and are safe for their intended use. We are accredited to carry out the following standardised mechanical tests:

- Tensile Test at Room Temperature with forces between 1kN and 500kN (Ambient Temperature Tensile Test)

- Tensile Test at High Temperature with forces between 10kN and 500kN and temperatures up to 650°C (Elevated Temperature Tensile Test)

- Charpy Impact Test between room temperature and -80°C, or at -196°C, using 'V' and 'U' shaped notches with optional lateral expansion and % shear measurands.

- Izod Impact Strength Test

- Bend Test

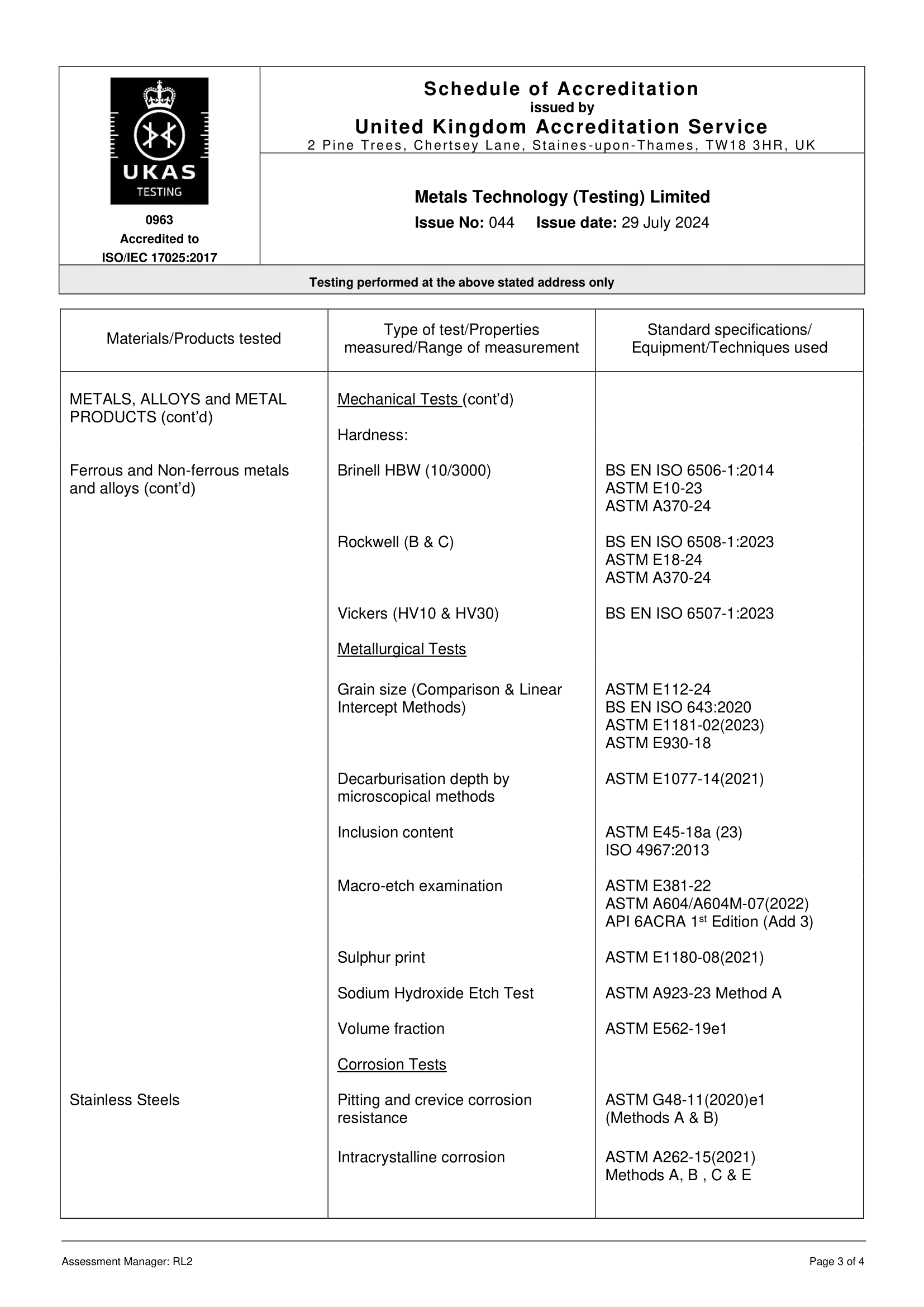

- Brinell HBW (10/3000) Hardness Test

- Rockwell (B and C) Hardness Test

- Vickers (HV10 and HV30) Hardness Test

Metallographic Tests

Metallographic tests carefully examine the physical structure of your material at the microscopic level. We are accredited to carry out the following standardised metallographic tests:

- Grain Size (Comparison & Linear Intercept Methods)

- Decarburisation Depth

- Inclusion Content

- Macro-Etch Examination

- Sulphur Print

- Sodium Hydroxide Etch Test

- Volume Fraction

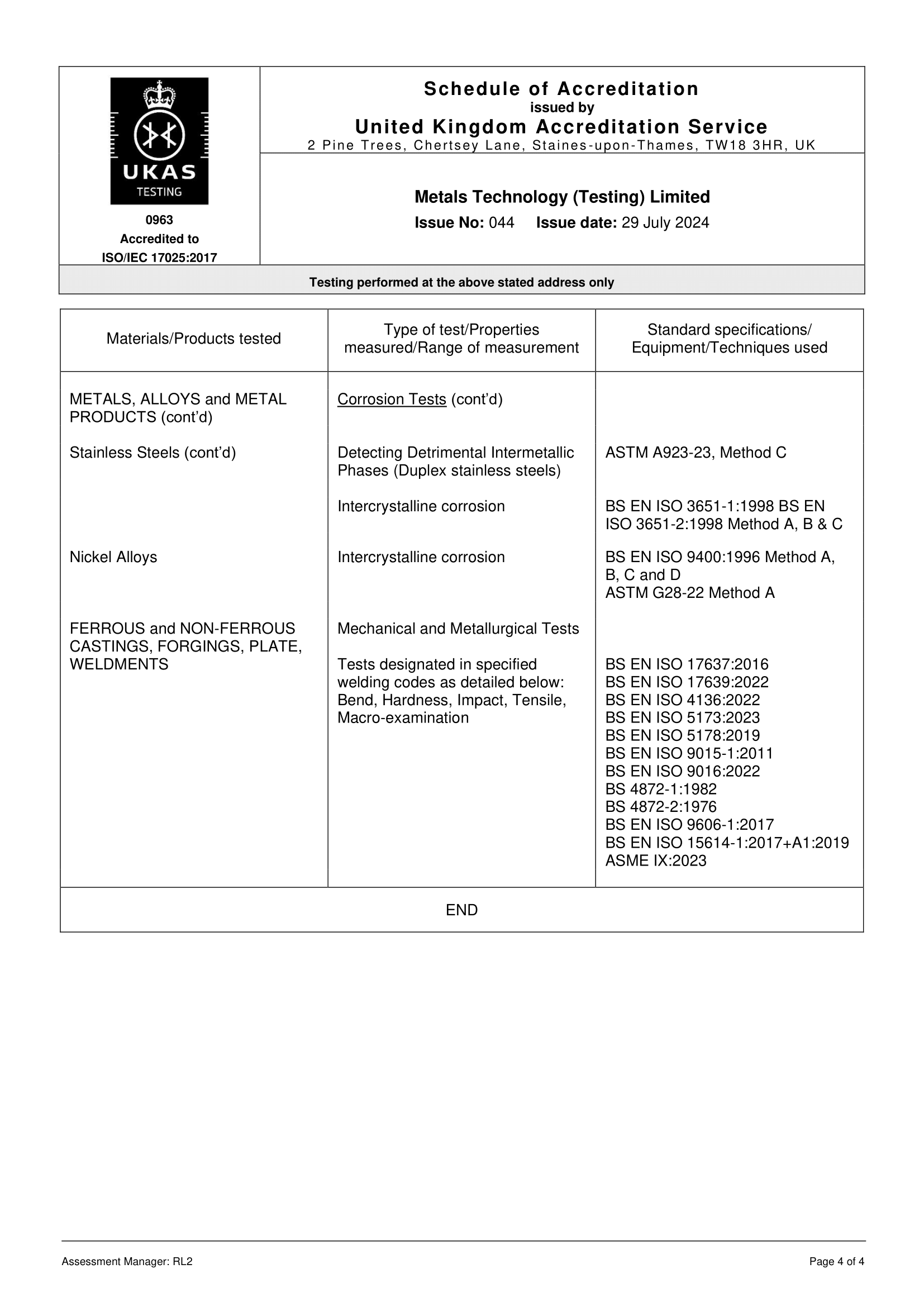

Corrosion Tests

Corrosion tests evaluate how your material degrades in corrosive environments to assess its resistance and predict long-term performance. We are accredited to carry out the following standardised corrosion tests:

- Pitting and Crevice Corrosion Resistance Test

- Detecting Detrimental Intermetallic Phases (Duplex Stainless Steels)

- Intercrystalline Corrosion Test